Facility and equipment

The tanks

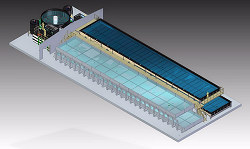

The

size of the production tanks in a raceway-style is 35 x 5m with a

height of 75cm. The water level is adjusted at about 50cm. The

resulting water volume per tank is about 80 cbm. The farm operates

with four tanks. Two tanks are in the floor, two tanks above in the

first storey (see picture). Each two tanks are connected to its own

water recirculation unit (RAS). The tanks are constructed in two

different ways. Two tanks are made with a special high density

concrete (Ultralith / Nanodur) which does not need any metal

framework; two other tanks are built with special Polyethylene

boards in black. Apart from regular production, the shrimp farm in

Grevesmühlen is being considered as a demonstration facility, thus

the application of the two different tank constructions.

The

size of the production tanks in a raceway-style is 35 x 5m with a

height of 75cm. The water level is adjusted at about 50cm. The

resulting water volume per tank is about 80 cbm. The farm operates

with four tanks. Two tanks are in the floor, two tanks above in the

first storey (see picture). Each two tanks are connected to its own

water recirculation unit (RAS). The tanks are constructed in two

different ways. Two tanks are made with a special high density

concrete (Ultralith / Nanodur) which does not need any metal

framework; two other tanks are built with special Polyethylene

boards in black. Apart from regular production, the shrimp farm in

Grevesmühlen is being considered as a demonstration facility, thus

the application of the two different tank constructions.

Water quality

The

farm is using artificial sea water which is based on fresh water

from a well. In the adaptation tanks for the larvae, the salinity is

initially adjusted of the origin of the larval stages from a farm in

Florida with about 36 psu. The salinity in the production tanks is

15psu. In an adaptation period, the salinity in the larval tanks is

decreased by 1psu/hour. The water temperature is kept around 30°C

in the production tanks. The air temperature in the facility is

about 31°C. This setting avoids significant evaporation of water

from the tanks. Thus, air humidity is kept closed to 70%. The water

filtration systems of the farm (RAS) operate continuously, keeping

the water clean and providing a healthy environment for the shrimp.

These recirculating systems work in several steps including solids

removal, biofiltration, CO2 removal, denitrification, protein

skimmer with ozonisation , UV-disinfection and oxygenation. The

removed sludge is discharged to the close sewage plant. The

operation of the farm based on RAS technique has the advantage that

the water quality can be precisely controlled and significantly

reduces the amount of water and space required. The water supply

rate is about 3-5% per day. The introduction of the water into the

tanks is managed by several inlets in order to ensure an equal water

quality in the entire tank. The water exchange rate in the

production tanks is 0.5 to 1 per hour.

The

farm is using artificial sea water which is based on fresh water

from a well. In the adaptation tanks for the larvae, the salinity is

initially adjusted of the origin of the larval stages from a farm in

Florida with about 36 psu. The salinity in the production tanks is

15psu. In an adaptation period, the salinity in the larval tanks is

decreased by 1psu/hour. The water temperature is kept around 30°C

in the production tanks. The air temperature in the facility is

about 31°C. This setting avoids significant evaporation of water

from the tanks. Thus, air humidity is kept closed to 70%. The water

filtration systems of the farm (RAS) operate continuously, keeping

the water clean and providing a healthy environment for the shrimp.

These recirculating systems work in several steps including solids

removal, biofiltration, CO2 removal, denitrification, protein

skimmer with ozonisation , UV-disinfection and oxygenation. The

removed sludge is discharged to the close sewage plant. The

operation of the farm based on RAS technique has the advantage that

the water quality can be precisely controlled and significantly

reduces the amount of water and space required. The water supply

rate is about 3-5% per day. The introduction of the water into the

tanks is managed by several inlets in order to ensure an equal water

quality in the entire tank. The water exchange rate in the

production tanks is 0.5 to 1 per hour.

Energy efficiency

The

facility has a heat demand of 70 kWh. The annual demand for heating

energy is supposed to be 600 MW which is provided from a biogas

facility for a reasonable rate.

The

facility has a heat demand of 70 kWh. The annual demand for heating

energy is supposed to be 600 MW which is provided from a biogas

facility for a reasonable rate.

Laboratory

The facility has its own laboratory, equipped with all necessary means to monitor water quality and production parameter in general.